In modern civil and structural engineering, the pursuit of precision, safety, and sustainability is inseparable from the ability to observe and interpret structural behavior in real time. SlabControl 5.0, developed by Adventum Tech, marks a major leap in structural-health monitoring (SHM), enabling continuous and intelligent assessment of concrete structures from the earliest curing stage to decades of service life.

Integrated Multi-Parameter Sensing

SlabControl 5.0 integrates advanced sensors to capture the most critical parameters governing concrete and structural performance: temperature, maturity (ASTM C1074), vibration, inclination, settlement, compression, tension, shrinkage, deformation, and bending. During early-age curing, uncontrolled vibrations or settlements can induce micro-cracks that compromise long-term durability. Continuous seven-day monitoring links vibration events directly with stiffness changes, enabling early detection of latent defects. After curing, the same system measures load-bearing response and long-term deformation, providing a unified dataset that connects material and structural behaviour.

Autonomous Power and Longevity

A 20-year battery lifetime gives SlabControl 5.0 autonomous operation without wiring or maintenance. Data are streamed to the Adventum Cloud for AI-based analysis, ensuring continuous insight into asset health and fatigue progression.

Engineering and Design Value

For engineers, SlabControl 5.0 closes the gap between finite-element simulation and in-situ performance. Real-time strength and deformation data calibrate analytical models, refine design assumptions, and enhance safety margins. The result is an evidence-based design environment where material evolution and load response are continuously validated against predictive models.

Investment Value for Asset Owners

For owners, long-term datasets transform asset management from reactive to predictive. Continuous monitoring reveals wear and fatigue trends, supports data-driven maintenance scheduling, and extends service life while minimizing unscheduled interventions. Structural integrity becomes measurable, auditable, and economically optimized.

Operational Efficiency for Contractors

Contractors gain immediate construction-phase benefits through automatic maturity tracking, optimized formwork release, and factual quality documentation. When claims or delays arise, vibration and settlement logs offer verifiable evidence of performance, improving transparency and reducing risk.

Applications Across Structural Domains

Piles

Detect load transfer, compression, and tension; verify foundation stiffness over time.

Bridges

Measure deck and pier deformation, fatigue, and bending behavior; enable predictive maintenance based on actual load history.

Wind-turbine foundations

Quantify cyclic loading reactions; assess fatigue after storms; enable lifetime extension and energy-output optimization.

Secant- or diaphragm-wall pits

Track wall displacement and pit stability; detect early soil-failure indicators.

Other loadbearing reinforced concrete structure

Remotely track structural performance in real time and identify overperformance or underperformance to optimize future designs or avoid any structural insufficiency risks.

Return on Investment (ROI): Data-Driven Efficiency and Cost Avoidance

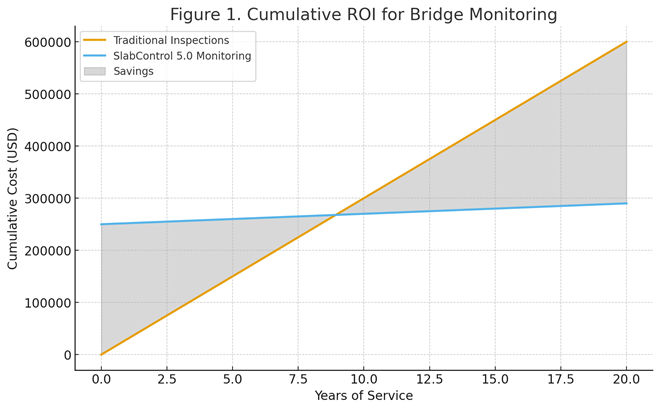

Bridge Case Study – Railway Infrastructure

Deploying 100 SlabControl 5.0 sensors on a critical railway bridge, each priced at USD 2 500 for 20 years, represents a total lifetime investment of USD 250 000. Conventional visual inspections cost USD 15 000 – 30 000 per occurrence, typically twice per year, leading to a 20-year expenditure of USD 600 000 – 1 200 000, excluding emergency surveys. By substituting frequent visual campaigns with continuous digital monitoring, owners achieve breakeven within five years and accrue exponential savings through reduced manual inspection, optimized maintenance, and fewer unplanned closures.

Cumulative ROI for Bridge Monitoring and Maintanance

A conceptual line graph illustrating cumulative savings versus time. – The x-axis represents service years (0–20). – The y-axis represents cumulative maintenance cost (USD). Two curves are shown: 1. Traditional inspections (steep linear increase to > USD 1 000 000 at Year 20). 2. SlabControl 5.0 monitoring (gentle slope reaching < USD 300 000). Their intersection near Year 5 marks the breakeven point; beyond it, the shaded area denotes net savings.

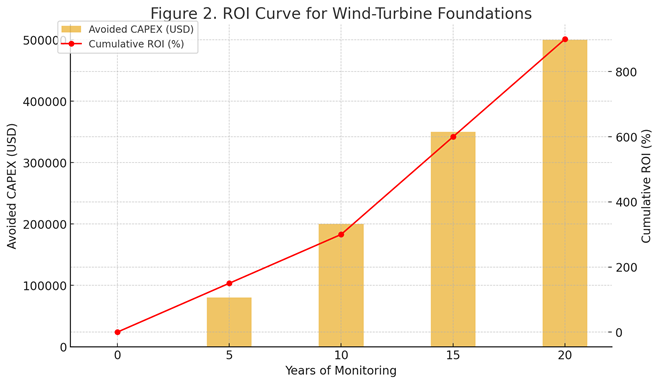

Wind-Turbine Foundation Case Study

A typical onshore wind turbine equipped with 10 SlabControl 5.0 sensors (~ USD 25 000 total) can avoid premature foundation reconstruction costing ~ USD 500 000 per turbine. Long-term fatigue tracking allows reuse of structurally sound foundations for 20–50 additional years, supporting repowering or turbine-upgrade projects. The deferred-capex benefit yields an internal rate of return exceeding 30 % per year and a cumulative ROI approaching 900 % over two decades.

ROI Curve for Wind-Turbine Foundation

A conceptual bar-and-line composite: – Bars show avoided capex and inspection costs per five-year interval. – The overlaid line shows cumulative ROI (%). By Year 20, the ROI surpasses 900%, with continued growth if foundations are reused for repowering cycles.

Final remarks

SlabControl 5.0 unifies structural sensing, long-term autonomy, and AI analytics into one instrument of continuous insight. For engineers, it offers precision validation; for asset owners, measurable longevity; for contractors, documented efficiency. When quantified economically, the system’s intelligence not only strengthens concrete—but also strengthens financial performance. With real-time, evidence-based monitoring, infrastructure evolves from a cost centre into a continuously optimized, data-driven asset.